What’s New on the Snake S3

The Trimax Snake S3 enhances turf mowing with smarter efficiency, lower ownership costs, and practical upgrades for professional operators.

The Cost of Safety: Why It Pays to Choose Trimax

Trimax mowers are engineered with safety at their core—protecting operators with equipment designed to meet and exceed today’s safety expectations.

Introducing the Snake S3

Discover the Trimax Snake, a cutting-edge mower designed with 35+ years of innovation and trusted by prestigious golf courses worldwide.

Introducing the Trimax Titan Bearing System

Introducing the Titan Bearing System—a groundbreaking innovation designed to deliver superior performance with no maintenance needs.

Introducing the SR (Single Roller) Range for Enhanced Long Grass Performance!

Building on the success of their double roller range, Trimax introduce a single roller range crafted to excel in long grass applications.

Trimax Unveils Revolutionary New Blade

Trimax NexaBlades represent a leap forward in mower blade technology, tailored for elite use on fine turf applications.

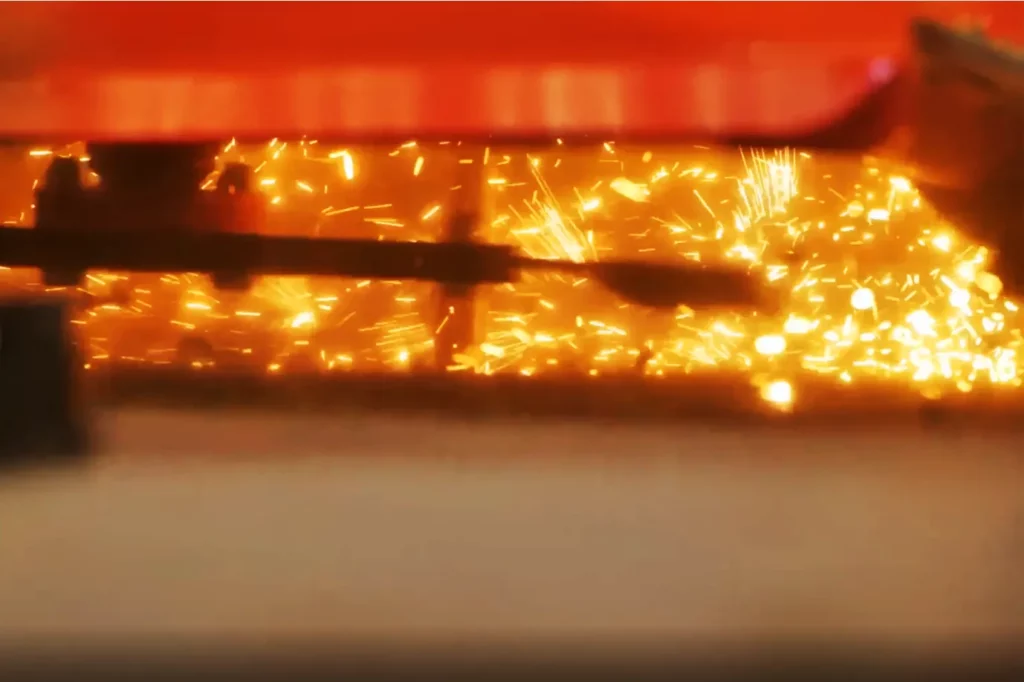

Behind the Scenes: The Rigorous Safety Testing of Trimax Mowers Unveiled

For Trimax Mowing Systems, world leader in flail and rotary cutting equipment, safety isn’t just a tick box exercise.

Trimax: Crafted in the UK Since 1998

From humble beginnings in New Zealand to becoming a significant contributor to the UK’s mower industry, Trimax persists in maintaining exceptional standards.

Trimax Unveils Game-Changing Electric-Drivetrain Development

Discover our game-changing electric drivetrain development – an innovation setting new standards in efficiency and operational flexibility.

Why is Looking at Total Cost of Ownership Important When Buying Machinery?

We look at why it’s important to consider the lifetime costs of your new machinery including productivity, fuel, maintenance, price and more.