When it comes to maintenance or repair, choosing genuine parts is the only way to guarantee the performance and life of your mower, explains Robert Todd, European Service Manager for Trimax Mowing Systems.

At a glance, genuine parts and pirate parts may appear to be similar; but scratch the surface and the issue becomes clear.

The Case for Genuine Parts

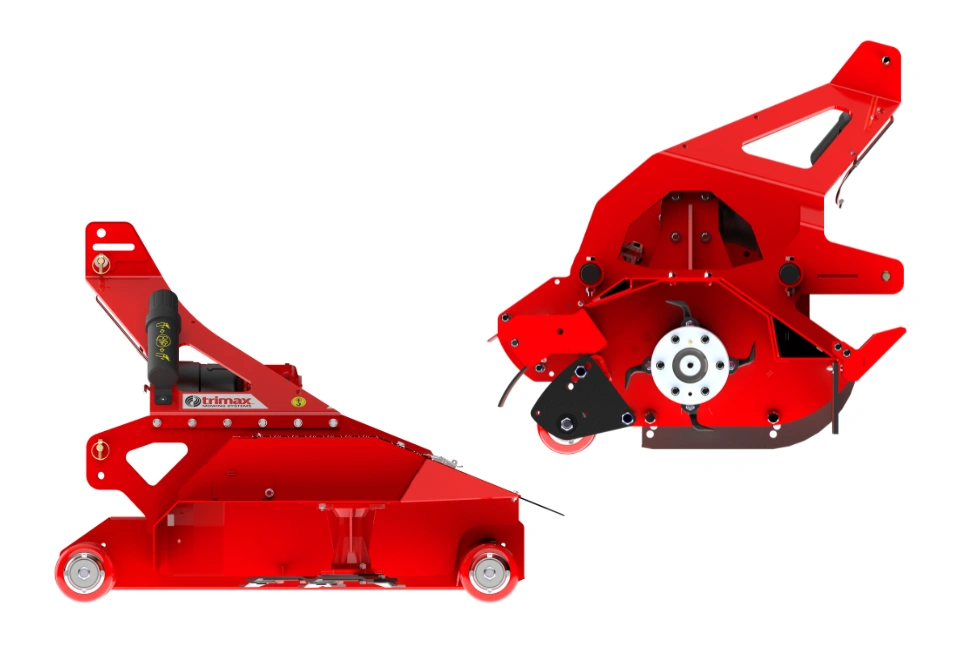

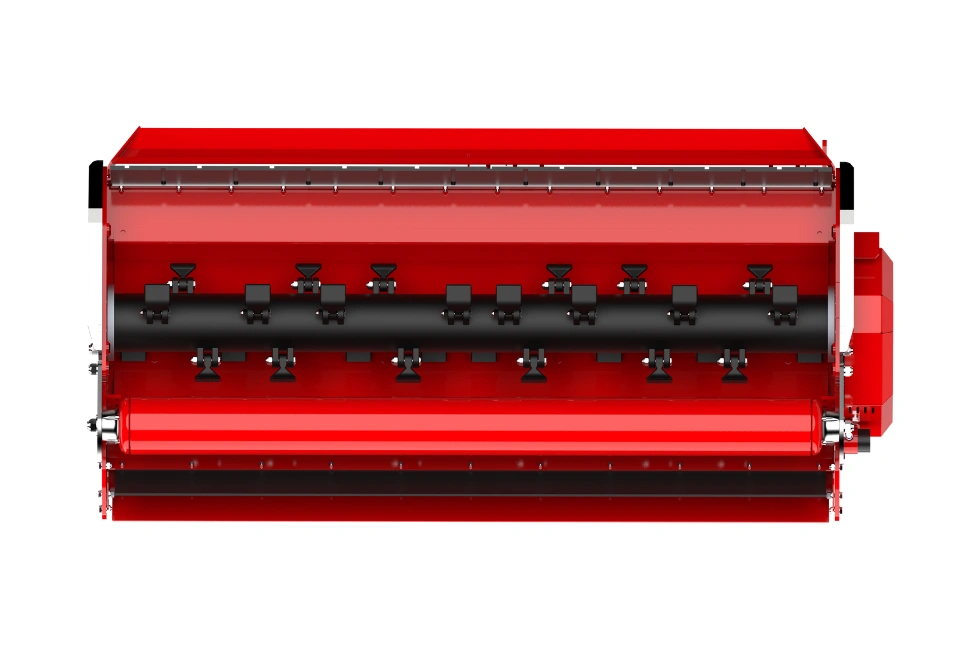

Genuine parts are exactly the same parts used to build the original machines. Years of research, development and testing have gone into them. They are made from high quality materials and in some instances individual parts perform more than one function.

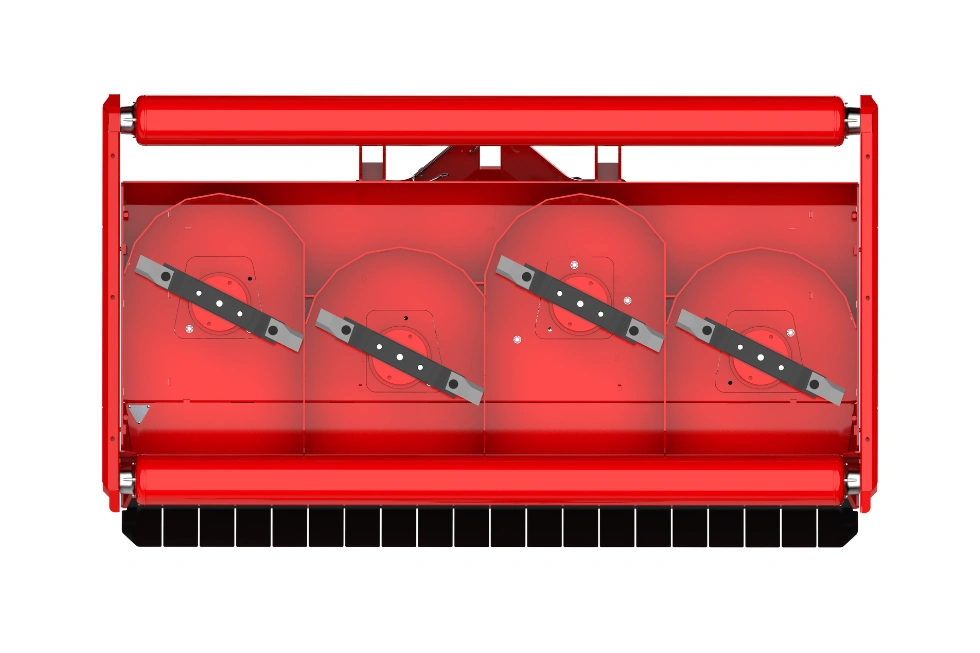

Take the blades on a Trimax mower as an example. Primarily meant to cut grass in diverse types of terrain, they also direct airflow ensuring the cutting chamber remains unobstructed and clippings are well distributed.

Beyond this, Trimax quality control ensures the blades are flawless – they can encounter obstacles like small logs and rocks without shattering and exiting the mower as a deadly piece of shrapnel. Safety and quality are integral parts of the Trimax design, ensuring the whole machine meets or exceeds all regional safety standards.

Ongoing Improvement

Continuous improvement is the cornerstone of companies like Trimax. Ensuring the pedigree means always having the latest technology and where possible new advances are designed to fit older models. Customers choosing genuine parts will have the safest, most efficient machines, and access to expert advice from the people who designed and manufactured the parts.

The Pirate Way

Pirate part vendors profess to make parts that are “just as good” as the real thing but cost significantly less. Really?

It is impossible for pirate parts to out-perform the original items and cost less because pirate parts are produced as a separate, profit-making exercise.

To maintain profit margins, pirates cut corners, lower specs and alter or delete pesky design details (remember the blades and flails), which might complicate manufacture.

For manufacturers like Trimax, parts are integral to their primary business – producing high quality machines. Parts are not produced as a stand-alone enterprise.

Other Factors For Consideration

Aside from the physical design and cost, there are some other important elements to consider before deciding between genuine or pirate parts.

- Safety – genuine parts have been tested to comply with safety regulations for maximum protection of machine and operator. Lower risk, greater peace of mind.

- Warranty – using non-genuine parts often voids manufacturer warranties, particularly if they go on to cause issues with the rest of the machine.

- Downtime – genuine parts are guaranteed to fit your machine first time, every time. Maximum uptime and performance.

- Expertise – only with genuine parts will you get expert advice from the people who designed, tested and manufactured the machine.

Where do You Stand?

It’s worth noting that genuine parts often aren’t as expensive as you might expect. Most manufacturers will price their parts competitively, meaning you can still get a good price: and in some cases, genuine parts can even be cheaper than pirate parts! It’s definitely worth checking with the original manufacturer before even considering going for a non-genuine part, as you may be surprised by how little real replacements actually cost, explains Robert Todd

For more information or to find out more about genuine parts, give us a call on 01933 652246 or [email protected]